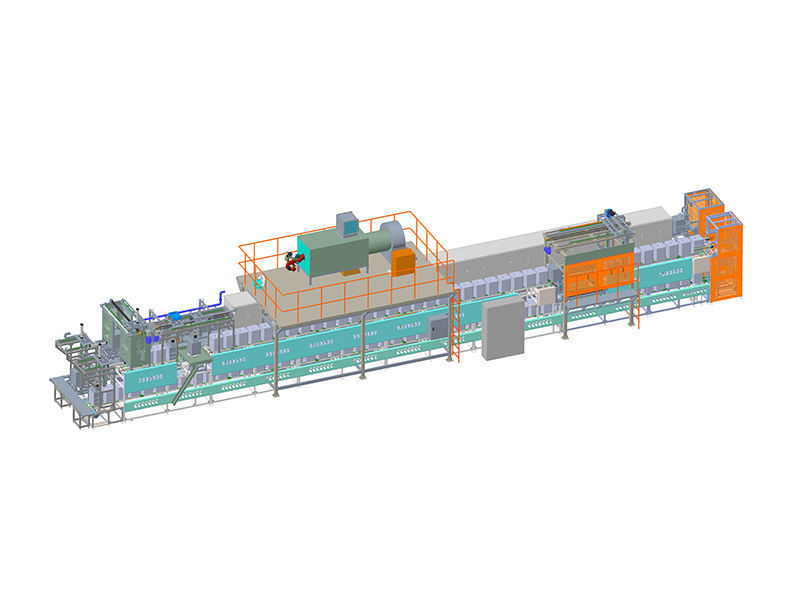

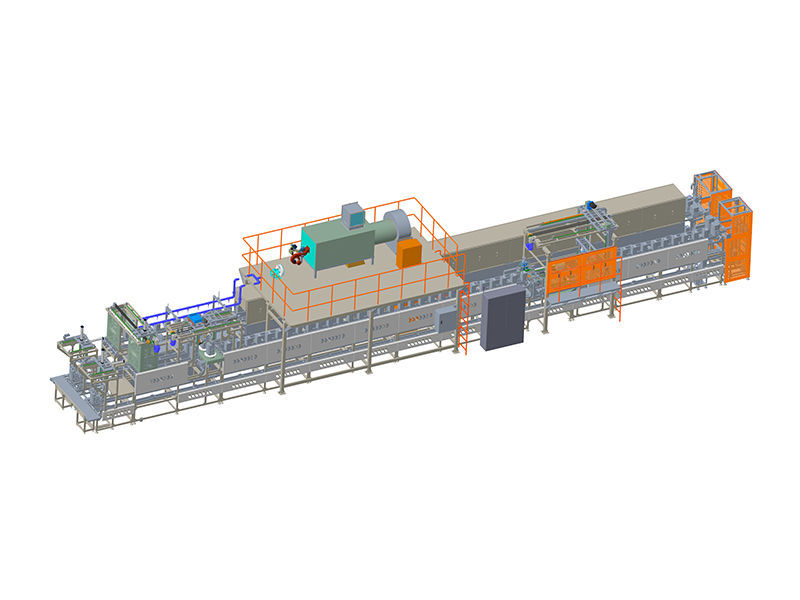

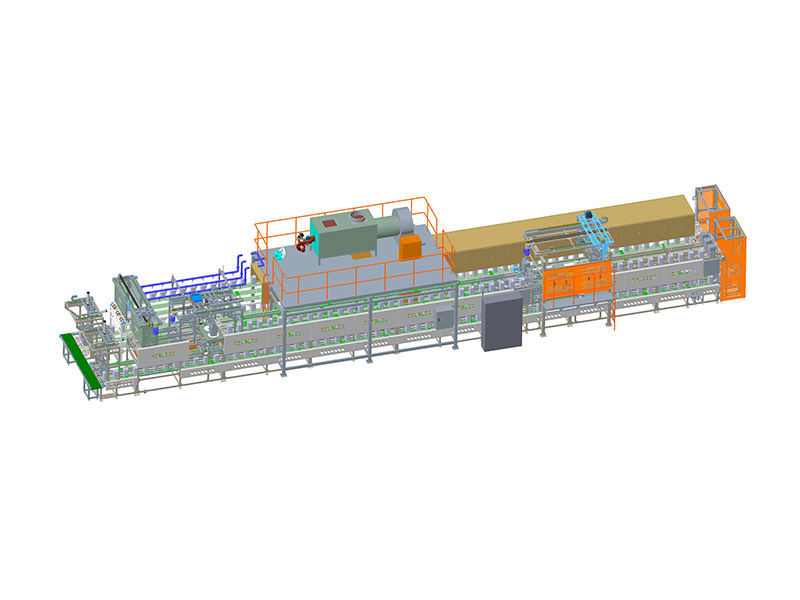

CHN-SX300 intelligent solid grouting line

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

Category:

Grouting series

Keywords:

Product Attachment:

Contact Us

Product Description

Functions and Features

This machine adopts a planar circulating working method to complete the slurry casting process of the blank, with:

1. Automatic slurry injection and pressure holding function, pressure holding time is adjustable within a certain range.

2. Automatic slurry discharge function, and with slurry discharge and air blowing function.

3. Automatic mold opening function, manual removal of blanks.

4. Automatic mold stacking and transfer function.

5. Realizes multi-point automatic control, overcurrent/phase failure protection and automatic prompt function, the whole machine performance is reliable.

6. Sleep running drying mode, which can safely and effectively dry the online molds when the equipment is not working.

7. This machine adopts a modular design, divided into single-unit and double-unit machines, installation, debugging, operation and maintenance are simple, energy-saving, environmentally friendly, labor-saving, and cost-reducing.

Applicable: Suitable for mass production of solid slurry casting products such as cup handles.

Technical Parameters

| Serial Number |

Name |

CHN-SX300 |

| 1 |

Equipment External Dimensions |

25400X3400X3300 |

| 2 |

Equipment Name |

Intelligent Solid Slurry Casting Line |

| 3 |

Total Weight |

8T |

| 4 |

Maximum Capacity |

180 molds/hour |

| 5 |

Number of Molds |

124 |

| 6 |

Maximum Mold Size |

Diameter 300 Height 75 |

| 7 |

Power Consumption |

Kw Power Supply: 380V/Ac±10%, three-phase five-wire, 50Hz |

| 8 |

Heating System |

Room temperature~65℃ adjustable, kiln waste heat can be used |

| 9 |

Gas Pressure |

3Kpa~5Kpa (Natural Gas) |

| 10 |

Compressed Air |

0.6~0.8Mpa (Clean Filtered), Consumption 0.2m3/min |

| 11 |

Environmental Requirements |

10%~90% RH【0~40℃】, 10%~55% RH【41~50℃】, Pollution Level 2 |

Next

Customer Message

Filling in your phone number and email address will help us contact you in time.

Related Products

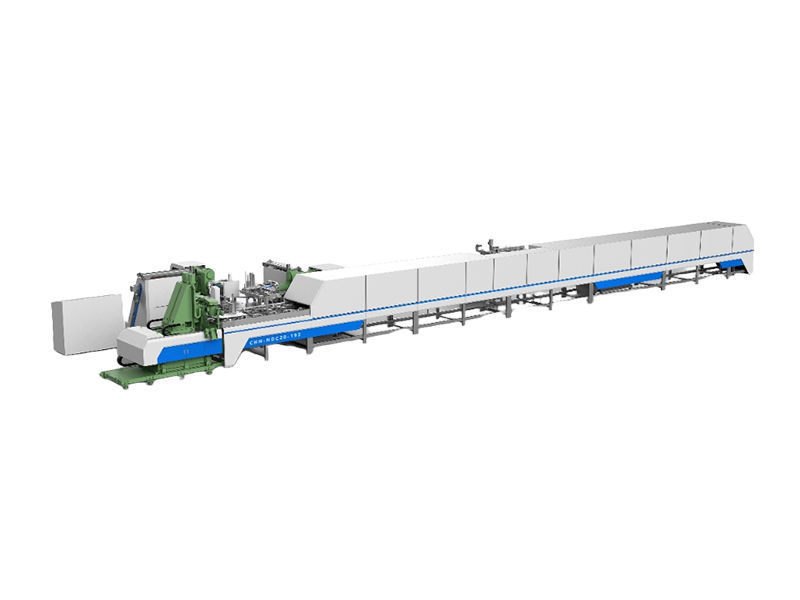

CHN-DC20 CNC roll forming line

This machine uses a flat tray to fix the mold and adopts a high-speed circulating working method. High-precision numerical control completes the blank rolling forming process.

View DetailsMLX1T - Single-mode centrifugal grouting machine

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

View DetailsCHN-MLX2T intelligent centrifugal grouting line

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

View DetailsCHN-MLX3T three-station centrifugal grouting machine

Realize multi-point automatic control, overcurrent/phase-loss fault protection and automatic prompt function, reliable overall machine performance

View Details