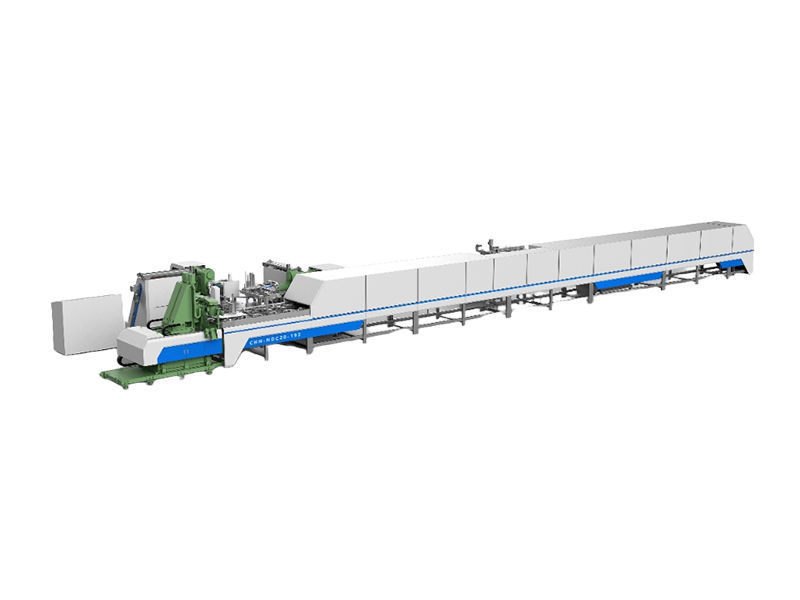

CHN-DC20 CNC roll forming line

This machine uses a flat tray to fix the mold and adopts a high-speed circulating working method. High-precision numerical control completes the blank rolling forming process.

Category:

Rolling series

Keywords:

Product Attachment:

Contact Us

Product Description

Functions and Features

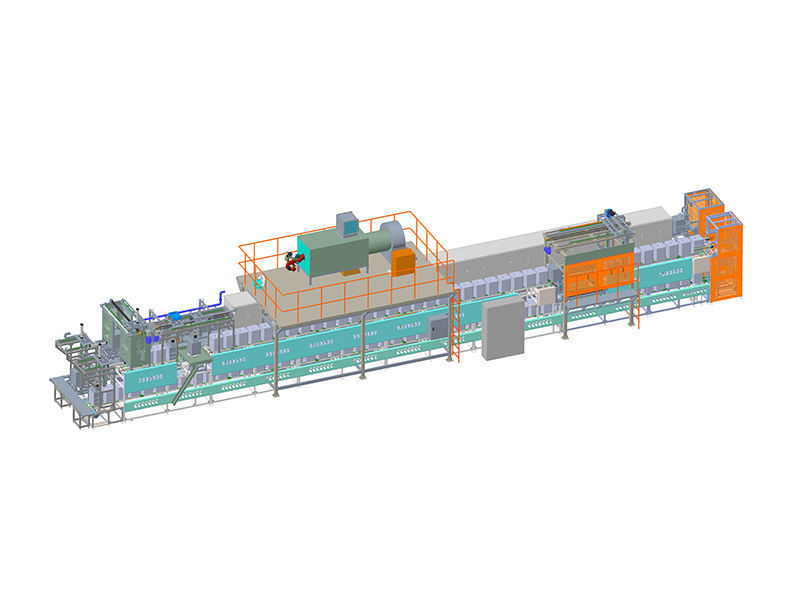

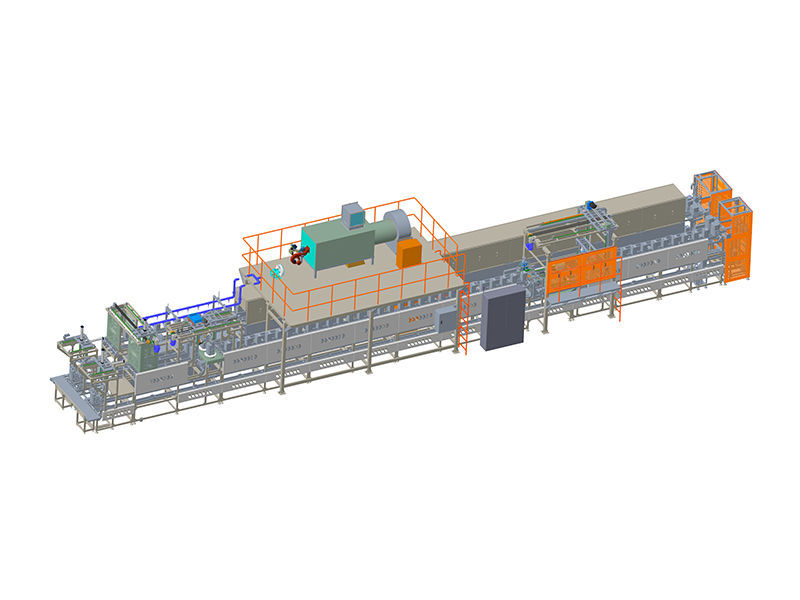

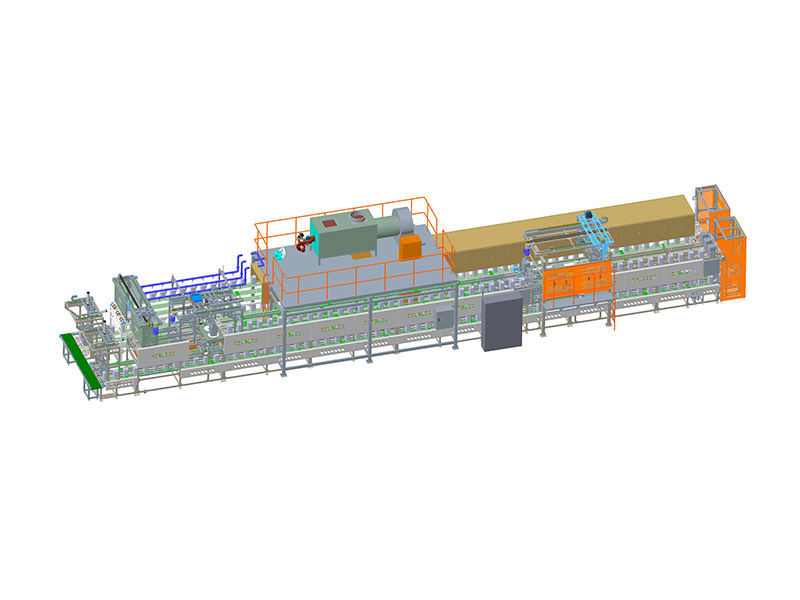

This machine adopts a high-speed circulating working method with a flat tray fixed mold, and high-precision numerical control completes the rolling and forming process of the blank. It has:

1. Automatic feeding three-axis vacuum mud extrusion function. Through the vacuum mud extruder, it continuously supplies two different sizes of mud materials for molding at the same time, solving problems such as frequent feeding, mud waste, and joint mud molding, making the mud material uniform, high vacuum, and good plasticity, improving product yield.

2. Using CNC rolling forming technology, the servo drive mechanism realizes the rapid movement of the rolling head, digital parameter adjustment and micro-movement control, realizing precise product forming.

3. Alignment injection drying function. Using a two-stage fire ratio adjustment natural gas burner for heating, the outlet is aligned with the product injection, effectively solving problems such as inaccurate combustion temperature control, incomplete combustion, uneven drying, thermal cracking, and deformation.

4. Positioning mold tray transmission method, making the mold operation more stable and efficient.

5. Automatic cutting and feeding, automatic picking and placing functions. The automatic transplanting device realizes the precise placement of mud and the transfer of blanks.

6. Automatic fine blank function. After the blank is demolded, the blank is automatically erected, the mouth is washed, and the automatic center positioning function is performed.

7. The product forming size adjustment range is large, and it can flexibly adapt to the needs of different production process parameters and quickly switch product production specifications.

8. The equipment has a high degree of intelligence, stable operation, and reliable safety; the advanced hot air system design effectively guarantees the service life of the mold (more than 600 times).

9. The application of remote network control of equipment solves problems such as rapid fault diagnosis and troubleshooting after sales.

10. This machine adopts a modular design, and the installation, debugging, operation, and maintenance are simple, energy-saving, environmentally friendly, labor-saving, and cost-reducing.

Applicable: Suitable for continuous production of standard rotary body rolling forming products.

Technical Parameters

| Serial Number | Name | CHN-DC20 |

| 1 | Equipment External Dimensions | 15500 ×3800×2200 |

| 2 | Forming Method | CNC Rolling |

| 3 | Total Weight | 8T |

| 4 | Maximum Production Capacity | 1200 pieces/hour |

| 5 | Number of Molds | 128 |

| 6 | Number of Rolling Heads | 2 |

| 7 | Maximum Mold Size | φ 200 × H180 |

| 8 | Maximum Forming Size | φ90 ×H100 (wet blank) |

| 9 | Power Consumption | 20Kw Power supply: 380V/Ac±10%, three-phase five-wire, 50Hz |

| 10 | Drying Heat | Approximately 50,000 Kcal/hr |

| 11 | Heating System | Adjustable from room temperature to 65℃, kiln waste heat can be used |

| 12 | Gas Pressure | 3Kpa~5Kpa (Natural Gas) |

| 13 | Compressed Air | 0.6~0.8Mpa (Clean Filtered) |

Previous

Previous

Customer Message

Filling in your phone number and email address will help us contact you in time.

Related Products

CHN-DC20 CNC roll forming line

This machine uses a flat tray to fix the mold and adopts a high-speed circulating working method. High-precision numerical control completes the blank rolling forming process.

View DetailsMLX1T - Single-mode centrifugal grouting machine

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

View DetailsCHN-MLX2T intelligent centrifugal grouting line

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

View DetailsCHN-MLX3T three-station centrifugal grouting machine

Realize multi-point automatic control, overcurrent/phase-loss fault protection and automatic prompt function, reliable overall machine performance

View Details