CHN-NC25 Multifunctional CNC Roll Forming Line

Category:

Rolling series

Keywords:

Product Attachment:

Contact Us

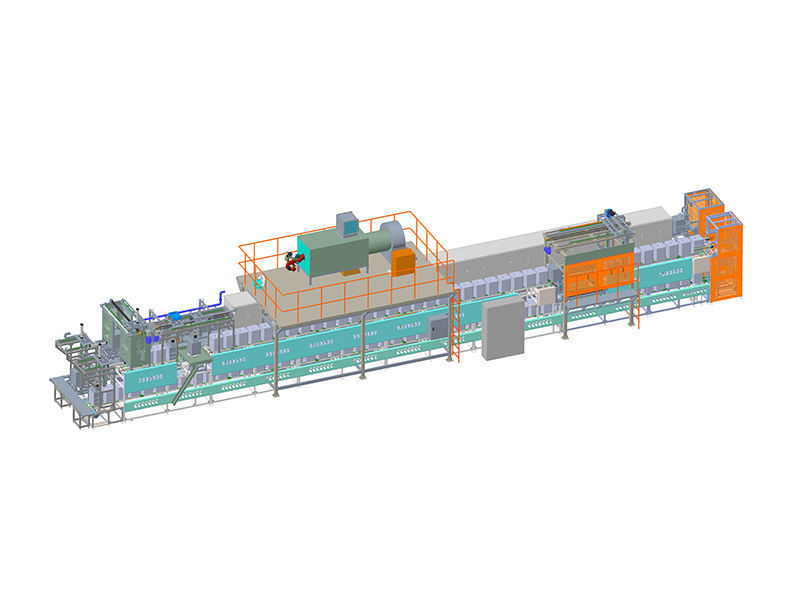

Product Description

Technical Parameters

| Serial Number |

Name |

CHN-NC25 |

| 1 |

Equipment Dimensions |

16000×4500×2500 |

| 2 |

Forming Method |

CNC Roll Pressing |

| 3 |

Total Weight |

10T |

| 4 |

Maximum Production Capacity |

500 pieces/hour |

| 5 |

Number of Molds |

96 |

| 6 |

Number of Rollers |

& |

| 7 |

Maximum Mold Size |

φ248 ×H180 |

| 8 |

Maximum Forming Size |

φ120 ×H140 (wet blank) |

| 9 |

Power Consumption |

25Kw Power Supply: 380V/Ac±10%, three-phase five-wire, 50Hz |

| 10 |

Drying Heat |

Approximately 40,000Kcal/hr |

| 11 |

Heating System |

Adjustable from room temperature to 65℃, can utilize kiln waste heat |

| 12 |

Gas Pressure |

3Kpa~6Kpa (Natural Gas) |

| 13 |

Compressed Air |

0.6~0.8Mpa (Clean Filtered), Consumption 0.2m4/min |

| 14 |

Environmental Requirements |

10%~90% RH【0~40℃】,10%~55% RH【41~50℃】,Pollution Level 2 |

| 15 |

Forming Method |

Negative Mold Forming |

Customer Message

Filling in your phone number and email address will help us contact you in time.

Related Products

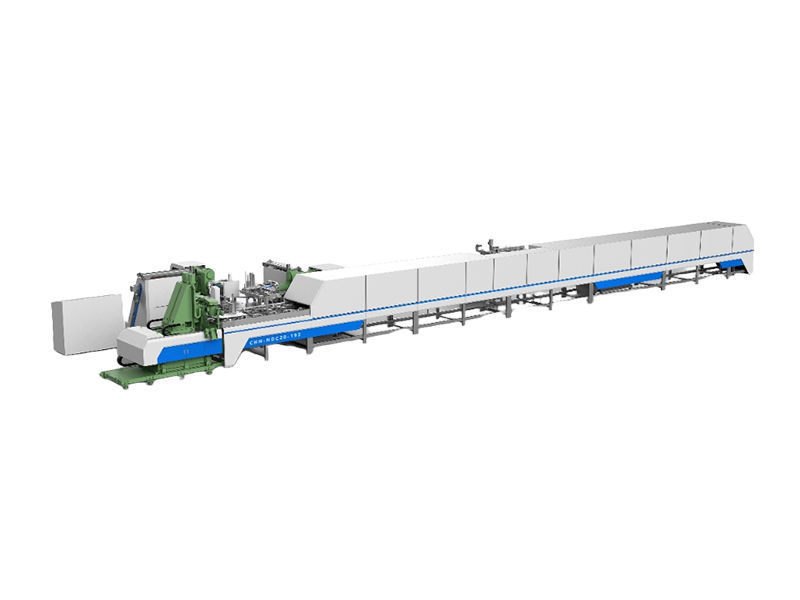

CHN-DC20 CNC roll forming line

This machine uses a flat tray to fix the mold and adopts a high-speed circulating working method. High-precision numerical control completes the blank rolling forming process.

View DetailsMLX1T - Single-mode centrifugal grouting machine

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

View DetailsCHN-MLX2T intelligent centrifugal grouting line

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

View DetailsCHN-MLX3T three-station centrifugal grouting machine

Realize multi-point automatic control, overcurrent/phase-loss fault protection and automatic prompt function, reliable overall machine performance

View Details