CHN-YX01 CNC special-shaped synchronous roll forming machine

This machine adopts a dual-die reciprocating cycle operation method, with synchronous forming of irregular shapes, and high-precision CNC rolling to complete the blank forming process.

Category:

Rolling series

Keywords:

Product Attachment:

Contact Us

Product Description

Features

This machine adopts a dual-die reciprocating cycle working method for synchronous products of irregular shapes. High-precision CNC rolling completes the blank forming process, featuring:

1. The mechanical mechanism achieves a dual-die reciprocating cycle operation, reducing labor intensity, improving production efficiency, and ensuring operator safety.

2. The product forming size adjustment range is large, allowing flexible adaptation to the needs of different production process parameters and quick conversion of product production specifications.

3. The application of remote network control solves problems such as rapid fault diagnosis and troubleshooting after sales.

4. Using CNC rolling forming technology, the entire machine forming process is driven by a servo motor, achieving rapid movement of the rolling head, digital parameter adjustment, and micro-movement control, resulting in precise product forming.

5. The equipment has a high degree of intelligence, stable operation, and reliable safety; the advanced hot air system design effectively guarantees the service life of the mold (more than 600 times).

6. This machine adopts a modular design, making installation, debugging, operation, and maintenance simple, energy-saving, environmentally friendly, labor-saving, and cost-effective.

Applicable: Suitable for continuous production of synchronous rolling-formed products of irregular shapes.

Technical Parameters

| Serial Number |

Name |

CHN-YX01 |

| 1 |

Equipment Dimensions |

3000 ×2400×2800 |

| 2 |

Forming Method |

CNC Rolling |

| 3 |

Overall Weight |

5T |

| 4 |

Maximum Capacity |

3 pieces/minute |

| 5 |

Number of Workstations |

2 |

| 6 |

Number of Rolling Heads |

1 |

| 7 |

Maximum Mold Size |

535X435X260 |

| 8 |

Maximum Forming Size |

447X340xH176 (wet blank) |

| 9 |

Power Consumption |

10Kw Power Supply: 380V/Ac±10%, three-phase five-wire, 50Hz |

| 10 |

Compressed Air |

0.6~0.8Mpa (clean and filtered), consumption 0.2m7/min |

| 11 |

Environmental Requirements |

10%~90% RH【0~40℃】,10%~55% RH【41~50℃】,pollution level 2 |

| 12 |

Forming Method |

Resin Mold Forming and Gypsum Mold Forming |

Customer Message

Filling in your phone number and email address will help us contact you in time.

Related Products

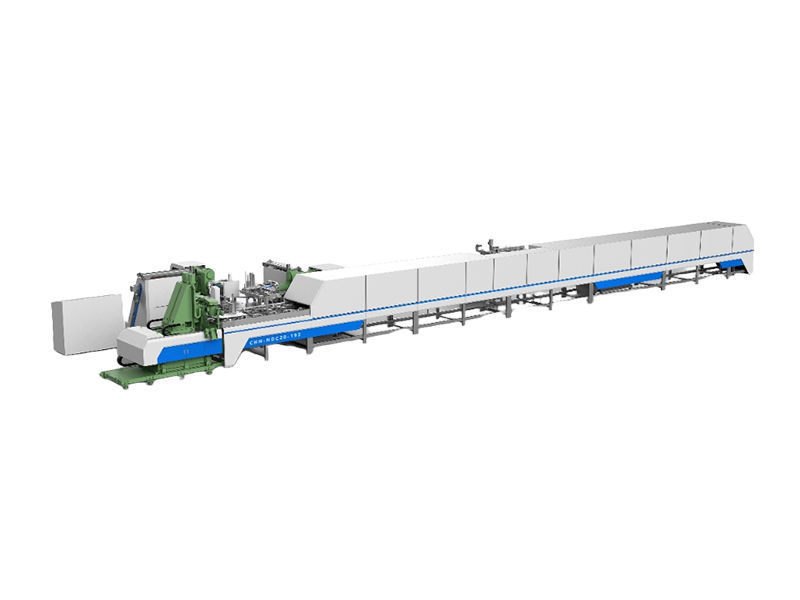

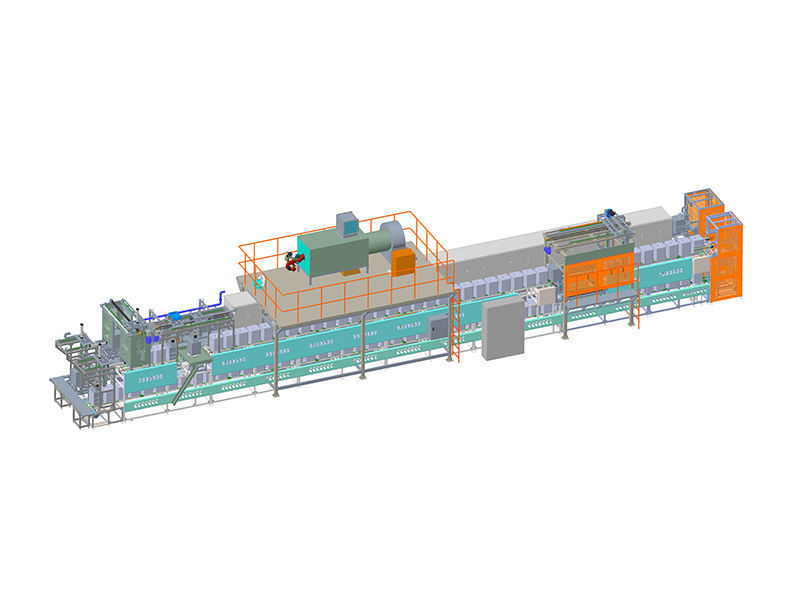

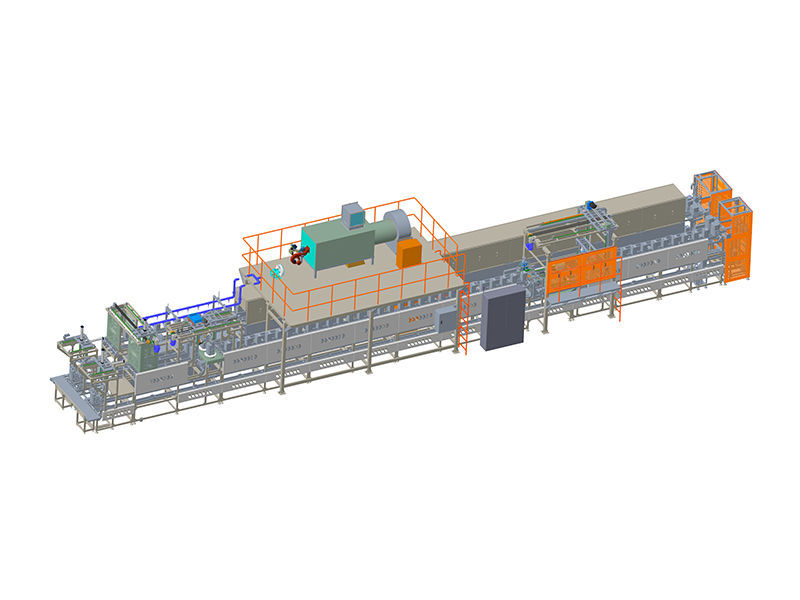

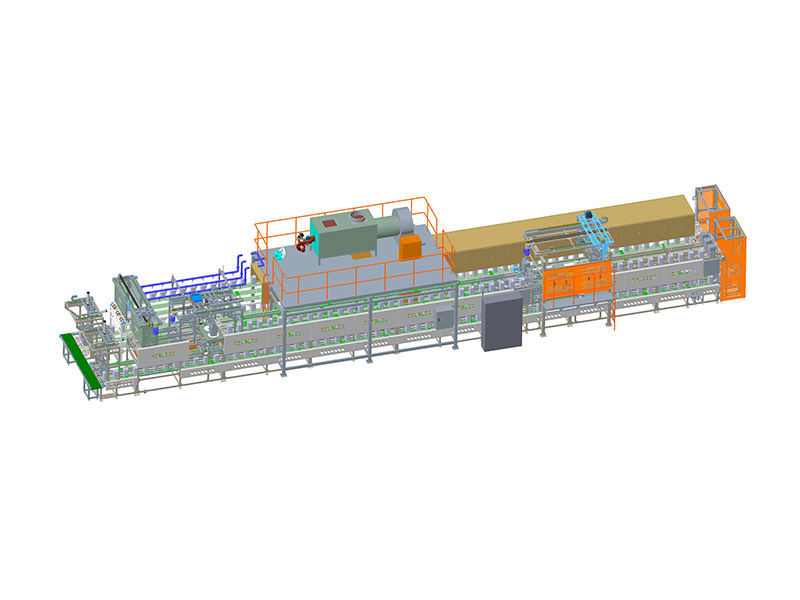

CHN-DC20 CNC roll forming line

This machine uses a flat tray to fix the mold and adopts a high-speed circulating working method. High-precision numerical control completes the blank rolling forming process.

View DetailsMLX1T - Single-mode centrifugal grouting machine

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

View DetailsCHN-MLX2T intelligent centrifugal grouting line

This machine uses a planar circulating working method to complete the slurry casting process of the blank.

View DetailsCHN-MLX3T three-station centrifugal grouting machine

Realize multi-point automatic control, overcurrent/phase-loss fault protection and automatic prompt function, reliable overall machine performance

View Details